Nopak Hydraulic Cylinders

Class 1, 2 and M

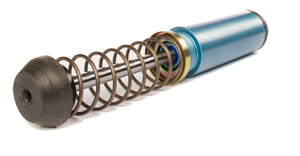

Class 1, and 2 Cast Head Cylinders use recessed gasketed tube seals and piston to O-ring seals as standard features. Class M Cast Head Cylinders offer all the mounts and features of Class 1, and 2 with an oversize rod and welded flanges.

Cylinder Tubes: Hard coated aluminum. Honed and chrome plated I.D. steel tubing is furnished for 10” thru 14” diameter cylinders. Class M cylinders have honed steel tubing with welded flanges.

Adjustable Cushion: Provides variable cushioning capacity, preventing noisy, damaging metal-to metal impact of piston against cylinder heads.

Special Molded Composition Wide Lip Self-Sealing Cup Packing: Furnished as standard.

Leakproof Gasket Seal: Between cylinder wall and head on Class 1 cylinders. Recessed gasket on Class 2, and Class M cylinders.

Quick-Opening Ball Check Valve: Assures quick starting under full power. Permits line pressure to act on full piston area instantaneously.

Positive Seal V Ring Stack Packing: Three Nylok inserts lock the threaded packing gland in place and maintain proper packing compressions. Larger diameters employ a piston rod bushing packing gland and bolted retainer ring.

Iron Alloy Cylinder Heads: For durability and long life. Through a large combination of standard and special heads, it is possible to furnish cylinders with mountings for Special Applications.

Piston Rod: Cylinders are regularly supplied with hard chrome plated steel piston rods. Threaded in one of three types of rod ends, fine thread series unless otherwise specified. Alternate oversize diameter rods can be accommodated in all standard rod head castings.

Class 1SVR Cast Head Cylinders

Class 1 SVR Cast Head Cylinders come standard with a piston rod packing box that is designed for double bearings and oversize rods, with bolt-on steel plate packing retainers.

The Piston Rod Packing Box is designed for Double Bearings and Oversize Rods with bolt-on steel plate packing retainers.

Easily adjustable Rod Seals are a multiple stack split V-Packing available in fabric-reinforced nitrile or fabric-reinforced Fluorocarbon.

The Piston Rod has a larger diameter; beyond the oversize OB rod.

The Piston Rod thread lengths are longer than standard Class 1, 2, M to incorporate a hex jam nut.

Class 3 High Pressure NFPA Square Head Cylinder

Class 3, High Pressure, NFPA Hydraulic Cylinder is available as large as a 20″ bore with over 20 mounting styles. The Class 3 is also available in an oversized, Mill Cylinder.

Improved Cushion Adjustment: Newly designed needle valve is interchangeable with current design and offers improved sealing characteristics.

Cushion Adjustment Needle: Needle valves and ball check drilling and machining are identical, making location of these functions interchangeable.

Tube Seal: Two-Step Pilot Recess Grooves afford Positive Controlled Squeeze on Pressure Sealed O-Ring, while Tubing locates concentrically against End Cap.

Piston: High strength, fine grain cast iron piston fitted with split “Tongue-seal” cast iron piston rings on either side of a homogenous “T” ring supplied with back-up rings. “T” ring furnished on all models; oversized are fitted with piston rings. The outboard piston rings effectively seal off initial shock loads and allow the “T” ring to provide a leak-proof piston seal with maximum life.

Heavy Wall: Steel tubing, precision honed with extra-long stones to provide over-lap and eliminate a spiral condition detrimental to long stroke cylinders. The resulting ultra-smooth finish provides maximum seal life.

Cushion Sleeves: Precision fitted with predetermined taper to provide a gradual deceleration and reduce shock.

Tie Rod: Material stressproof steel for maximum strength. Multiple tie rods in each corner are furnished on all models, 10” thru 20” diameter bores.

Piston Rod: High tensile 100,000PSI minimum yield stressproof steel, ground, polished, and flash chrome plated .0003/.0005 to provide a hard, long-wearing surface with low friction, but not corrosion resistant. Consult factory for special applications.

Rod Packing: Choice of self-adjusting to pressure, multi-lip split seal or continuous pre-loaded lip seal.

Packing Gland: Readily removable long bearing type. Rod packing easily replaced without loosening tie rods or dismantling cylinder.

Rod Wiper: Wipes rod clean and dry. Keeps foreign matter from entering cylinder, extending packing life.

Rod End Threading: Choice of standard catalog male and female thread types plus standard wrench flats.

Cushion Ball Check: Assures quick starting under full power; pressure acts on full piston area instantaneously.

End Caps: (Cylinder Heads) Precision Broached Steel Blocks

Class 6 Intermediate Pressure NFPA Square Head Cylinders

Class 6 is available for either hydraulic services up to 1500 PSI or for pneumatic services up to 250 PSI. Class 6 pneumatic cylinders have also been engineered to service low pressure hydraulic applications.

Improved Cushion Adjustment: Newly designed needle valve is interchangeable with current design and offers improved sealing characteristics.

Cushion Adjustment Needle: Needle valves and ball check drilling and machining are identical, making location of these functions interchangeable.

Piston Assembly: U-Cup packings, one piece piston.

Cushion Sleeves: Precision fitted with predetermined taper to provide gradual deceleration and reduce shock.

Cylinder Tubing:

AIR: Hard coated aluminum, or honed, non-corrosive steel, providing an extremely wear-resistant surface and low friction characteristics.

HYDRAULIC: Honed steel tubing standard (H6).

Piston Rod: High tensile 100,000PSI minimum yield stress proof steel, ground, polished, and flash chrome plated .0003/.0005 to provide a hard long-wearing surface with low friction but not corrosion resistant.

Tie Rod: Material alloy steel for maximum strength. Multiple tie rods in each corner are furnished on all 16” through 20” diameter cylinders.

Tube Seal: Two-step pilot recess grooves afford positive controlled squeeze on pressure sealed O-ring, while tubing locates concentrically against end cap.

Cushion Ball Check: Assures quick starting under full power; pressure acts on full piston area instantaneously.

Rod Packing: Choice of self-adjusting to pressure, multi-lip split seal or continuous pre-loaded lip seal.

Packing Gland: Readily removable long bearing type, held in place with socket head cap screws. Rod packing easily replaced without loosening tie rods or dismantling cylinder.

Rod Wiper: Wipes rod clean and dry. Keeps foreign matter from entering cylinder, extending packing life.

Rod End Threading: Choice of standard catalog male and female thread types plus standard wrench flats.

End Caps: (Cylinder Heads) Precision steel blocks.

We offer the above from the following Brands