American Tie Rod Pneumatic Cylinders

TIE ROD PNEUMATIC CYLINDERS

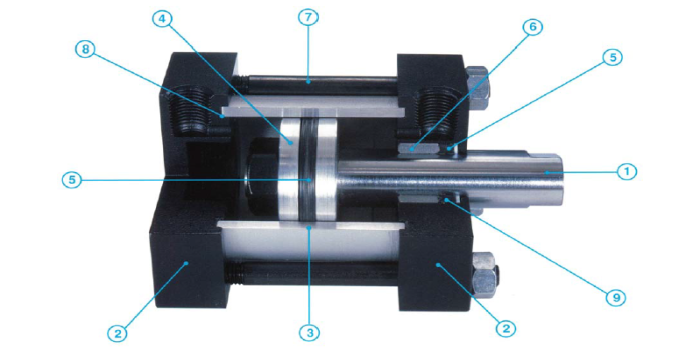

Mini-Pak Series Cylinders

American’s Mini-Pak® Series Cylinders are designed for applications requiring space saving configurations and NFPA mounting styles. The MiniPak® Series cylinders are available in 1-1/2″, 2″, 2-1/2″ 3-1/4″, 4″, 5″, 6″ and 8″ bore sizes in a variety of mounting styles.

Hard Chrome-Plated & Polished Piston Rod: Minimum yield of 100,000 PSI. High tensile strength steel provides for reliable performance and longer rod seal life.

Solid Anodized Aluminum Alloy Heads: Designed for corrosion resistance and extra strength.

Aluminum Alloy Tube 6063-T832: PSI of 35,000. Hard coated I.D. resists scoring and wear.

Aluminum Alloy Piston: Provides excellent characteristics against the hard coated I.D. cylinder body.

Seals: Piston and rod seals are of Quad-Ring design to provide for low dynamic friction and positive sealing. O-Ring or U-Cup piston seals are available in 11/2″ thru 5″ bores. (6″ & 8″ bores are standard with UCup piston seals.)

Cast Iron Rod Bushing: Compatible with the hard chrome plated rod. Close grain cast iron bearing provides maximum wear resistance for long life.

Tie Rods: High strength steel to maintain compression on tube end seals.

Tube End Seals: Fiber and nitrile base elastomer acting as a binder for positive sealing.

Teflon Back-Up Washer: Wipes the rod clean and keeps out contamination.

Factory Lubricated: Cylinder bodies are lubricated with AC 2119 Teflon-based compound.

Pretested: The quality of each cylinder is assured by testing each unit for leakage prior to shipment. Quality control provides added value to American Cylinders.

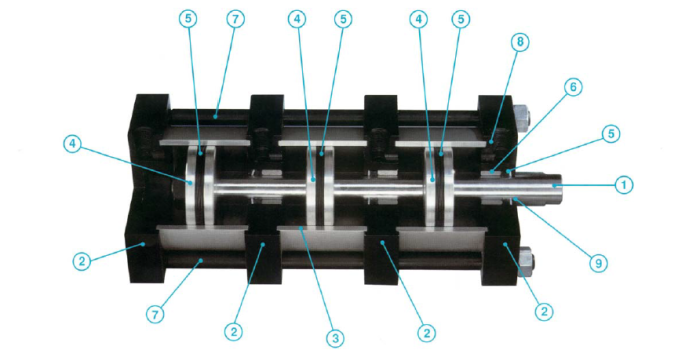

MSP (Multi Stage Power) Air Cylinders

American’s MSP® Multi-Stage Power Air Cylinders are designed for applications requiring an output force several times that of a single piston air cylinder of the same pressure and bore size.

MSP® cylinders are constructed with multiple pistons on a single rod separated by ported block partitions. When air pressure is applied simultaneously through the individual stages, output force is increased proportionally.

Hard Chrome-Plated & Polished Piston Rod: Minimum yield of 100,000 PSI. High tensile strength steel provides for reliable performance and longer rod seal life.

Solid Anodized Aluminum Alloy Heads: Designed for corrosion resistance and extra strength.

Aluminum Alloy Tube 6063-T832: PSI of 35,000. Hard coated I.D. resists scoring and wear.

Aluminum Alloy Piston: Provides excellent characteristics against the hard coated I.D. cylinder body.

Seals: Piston and rod seals are of Quad-Ring design to provide for low dynamic friction and positive sealing. O-Ring or U-Cup piston seals are available in 11/2″ thru 5″ bores. (6″ & 8″ bores are standard with UCup piston seals.)

Cast Iron Rod Bushing: Compatible with the hard chrome plated rod. Close grain cast iron bearing provides maximum wear resistance for long life.

Tie Rods: High strength steel to maintain compression on tube end seals.

Tube End Seals: Fiber and nitrile base elastomer acting as a binder for positive sealing.

Teflon Back-Up Washer: Wipes the rod clean and keeps out contamination.

Factory Lubricated: Cylinder bodies are lubricated with AC 2119 Teflon-based compound.

Pretested: The quality of each cylinder is assured by testing each unit for leakage prior to shipment. Quality control provides added value to American Cylinders.

We offer the above from the following Brands