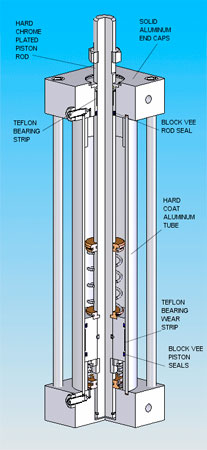

Motion Controls Tie Rod Cylinders (Non-NFPA)

Motion Controls “D” Series non-NFPA tie rod cylinders share common engineering principles between bore sizes to reduce costs instead of offering any and all possibilities. For example, the “D” Series does not offer different rod sizes in the same bore, but we do offer different rod ends. This saves the cost of stocking end caps with different combinations of rod and bore sizes as in an NFPA style cylinder.

TIE ROD CYLINDERS NON-NFPA

Motion Controls’ tie rod cylinders “D” Series does not offer different rod sizes in the same bore, but do offer different rod ends. These tie rod cylinders feature:

Non-Metallic Bearing

A specially compounded reinforced Teflon material is used for hte piston and rod bearings, assuring low friction characteristics. Bearing assembly is easily removed for quick replacement.

Non-Lube Operation

Long life D cylinders are specifically designed for non-lube operation

Cushions

High energy absorption poppet style adjustable cushions are available as a standard option. Cushion adjusting screw is normally located in position number 4.

Piston Rod

Hard chrome plated steel, ground and polished. Two wrench flats standard on all bore sizes. Full male national coarse threads are standard. All other threads available as options.

Tubing

Hard coated I.D. aluminum for corrosion resistance and low friction.

Seals

All dynamic seals are self-adjusting Block Vee Buna-N U-cups.

End Caps

Machined high strength aluminum alloy.

Pressure Rating

250 psi. air or “non-shock” hydraulic.

Temperature

Operating temperature range from a minimum of 10° F (-12°C) to a maximum of 200° F (93° C).

Cushions

Popper cushions can be specified for either or both ends of the Series “D” cylinder. Standard cushion length is one inch, with optional lengths of two, four, and six inches. Each standard cushion increases the cylinder length by one inch.

We offer the above from the following Brands